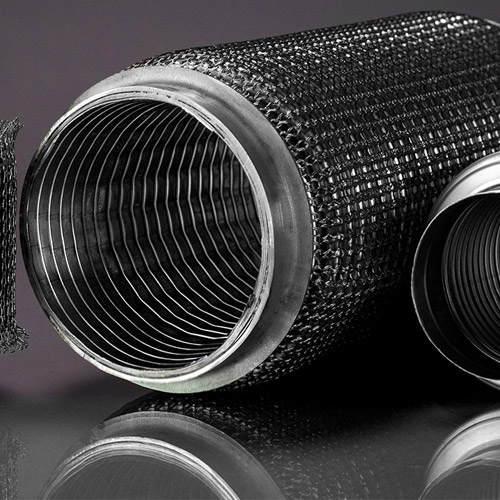

KnitMesh Technologies anti-vibration, sound attenuation and heat shields are highly effective absorbers of heat, noise and vibration energy.

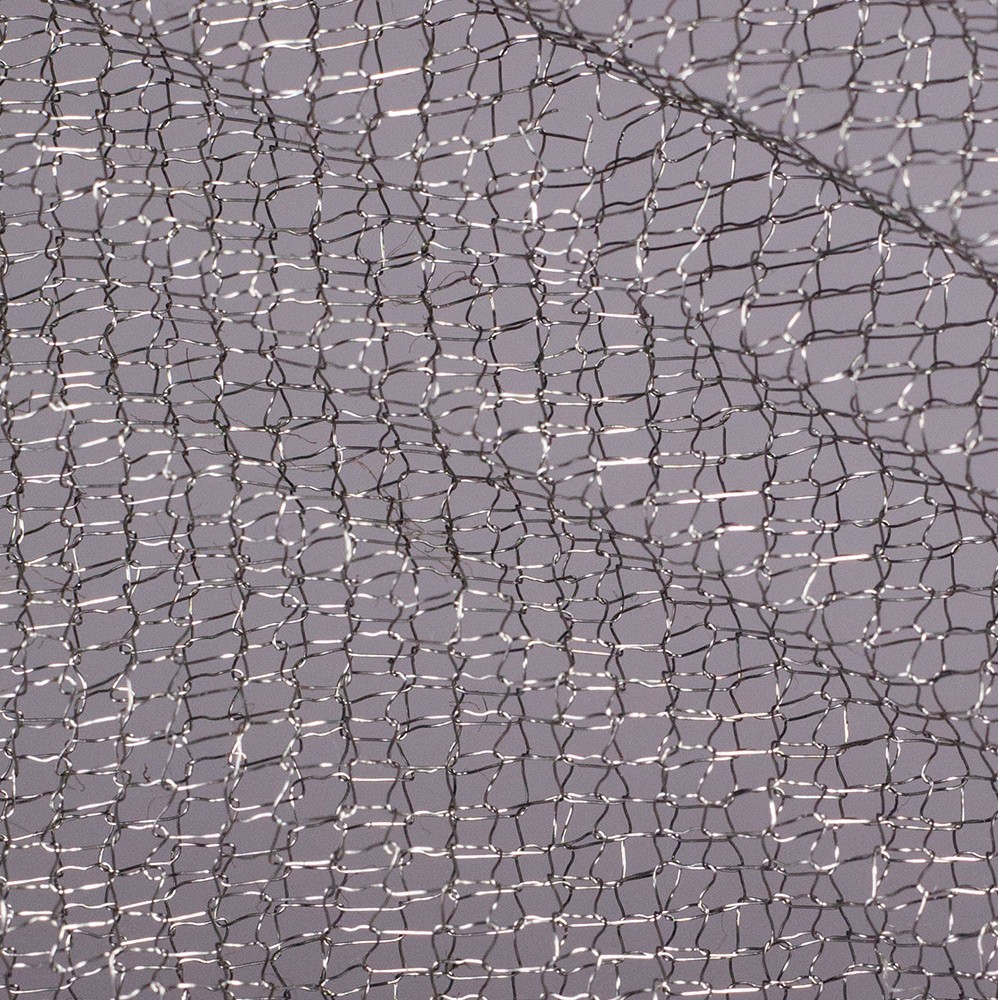

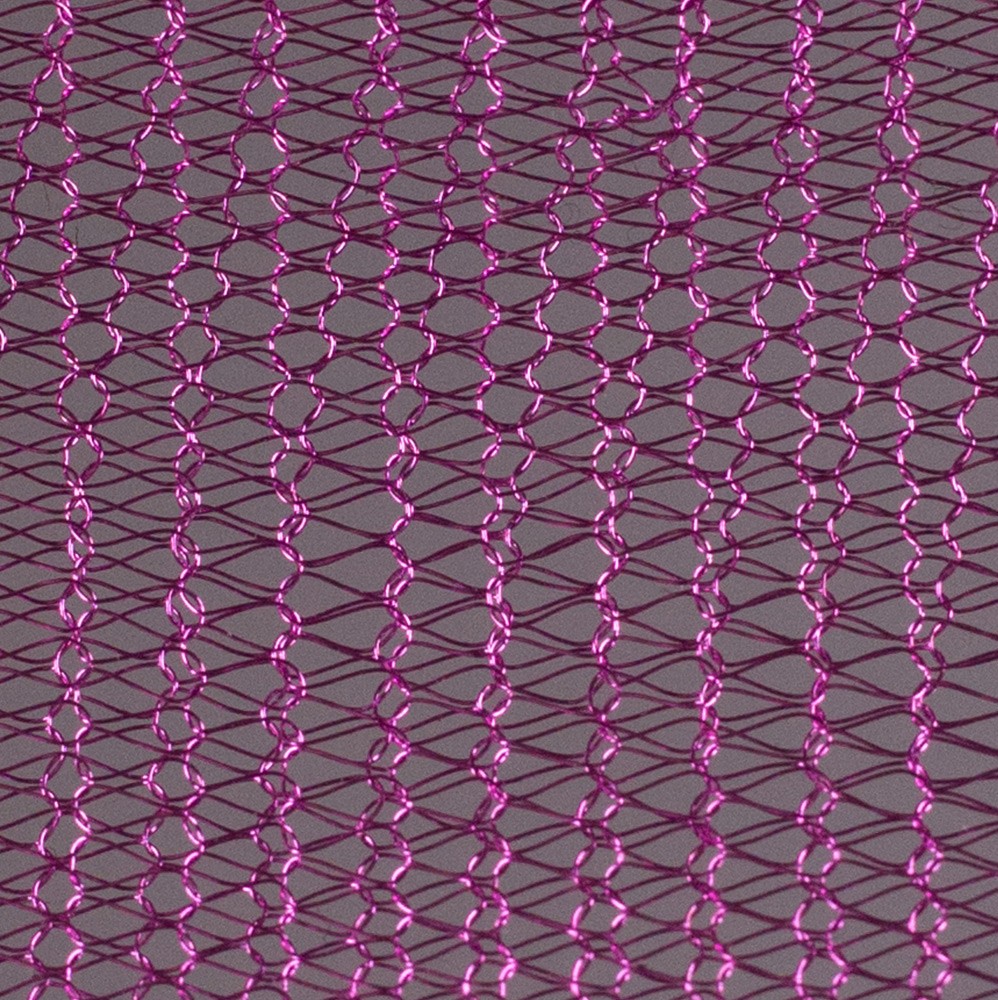

Knitted mesh has several properties that give it a unique ability to absorb energy. The result is a material ideal for use in many applications, able to reduce vibration, attenuate sound and dissipate heat.

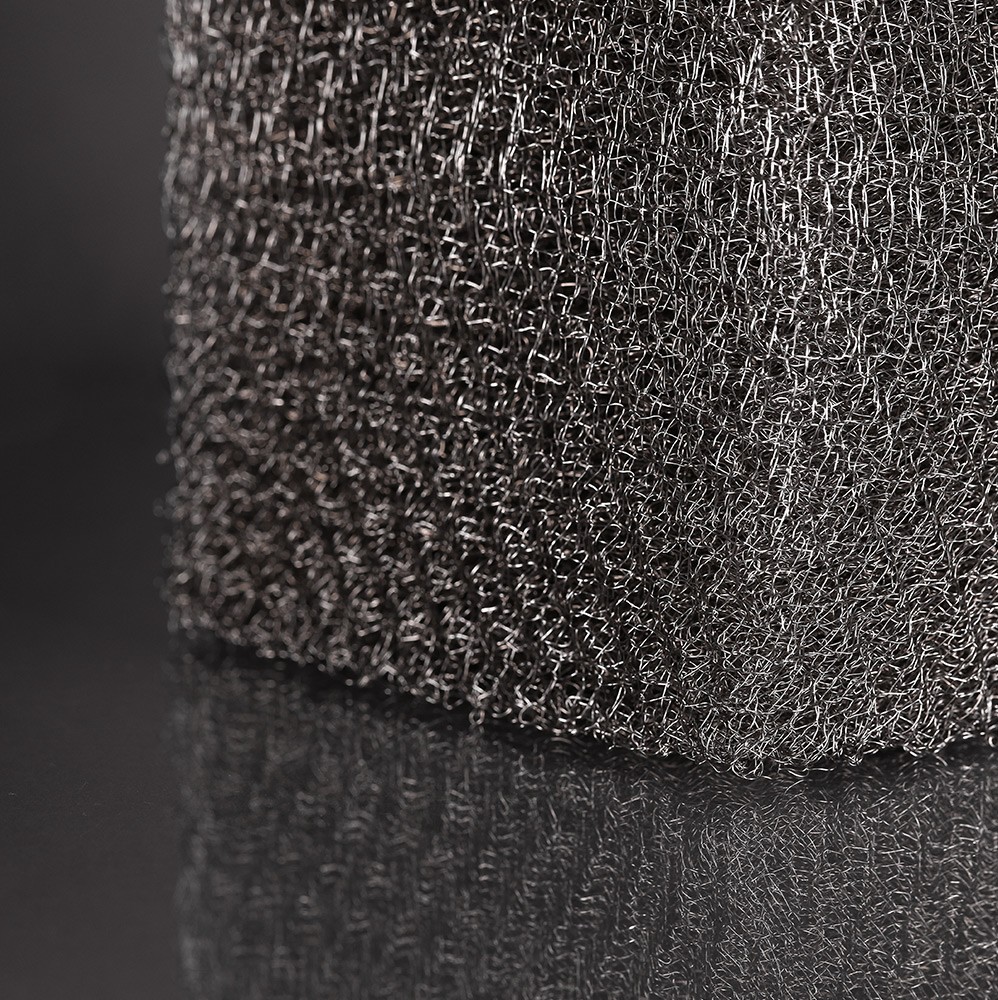

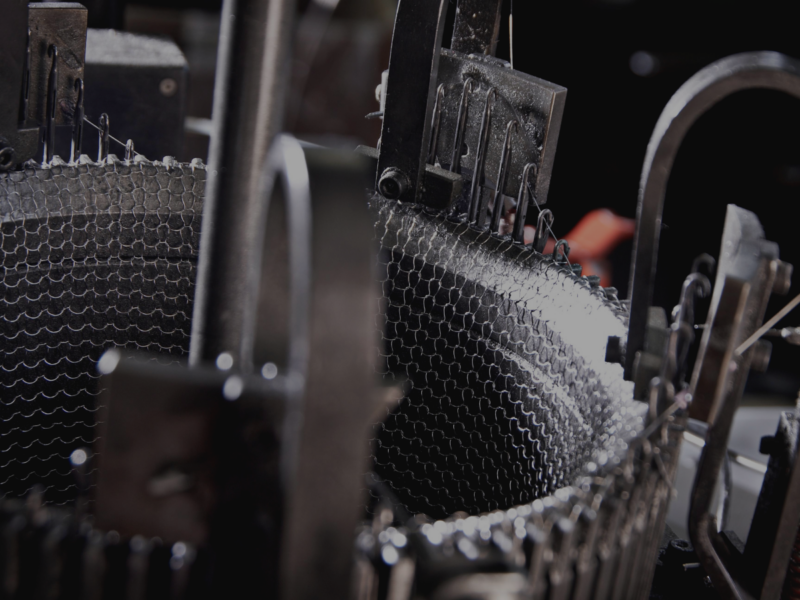

In the KnitMesh knitting process, wire loops are created that act like tiny springs. It is these springs that return to their original shape after being subjected to compression. The loops are also free to move in several directions, allowing the knitted material to have natural resilience and to vibrate when sound energy hits the knitted wires. When vibrating, the wires convert sound energy into thermal energy and, in doing so, create a sound-dampening effect.

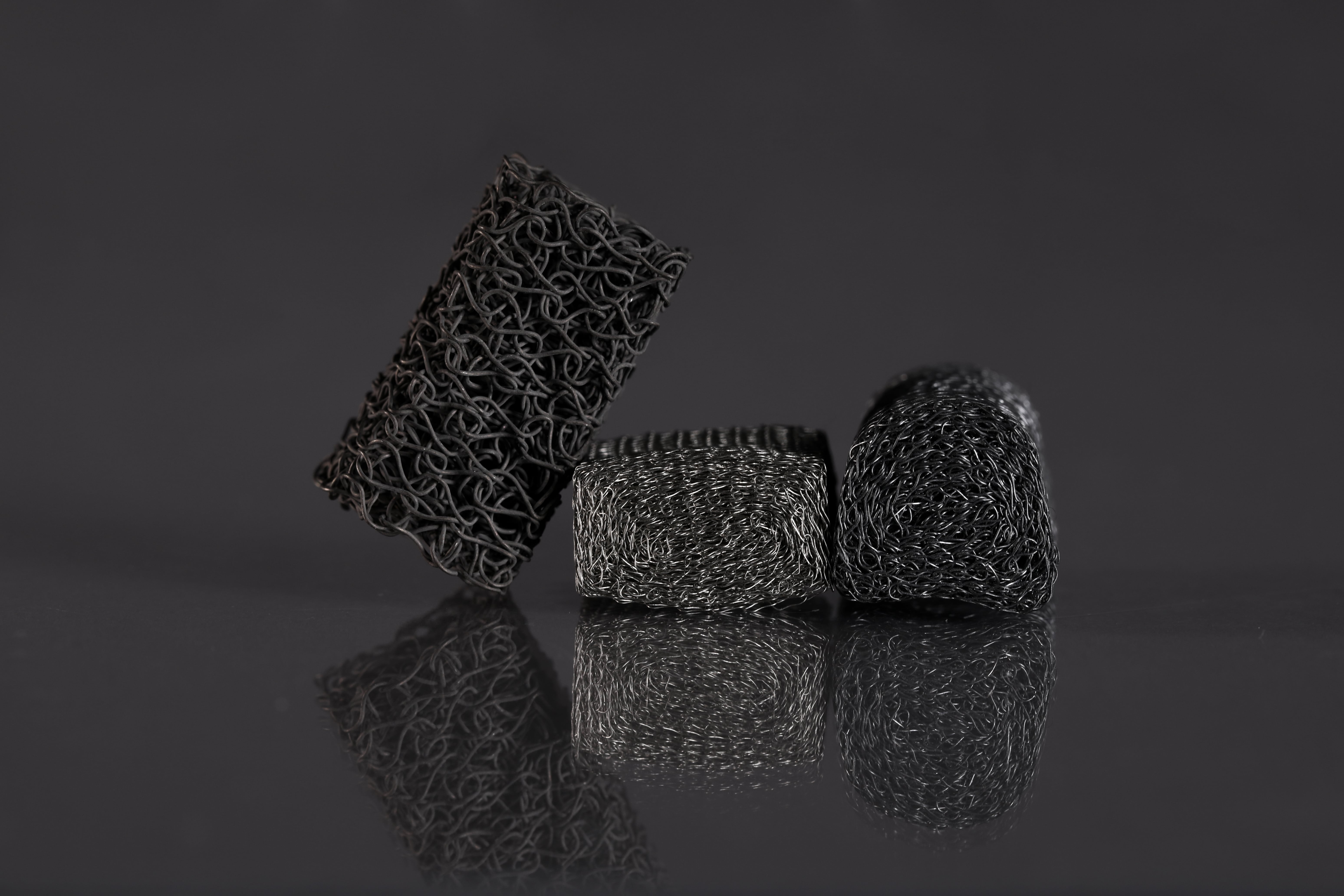

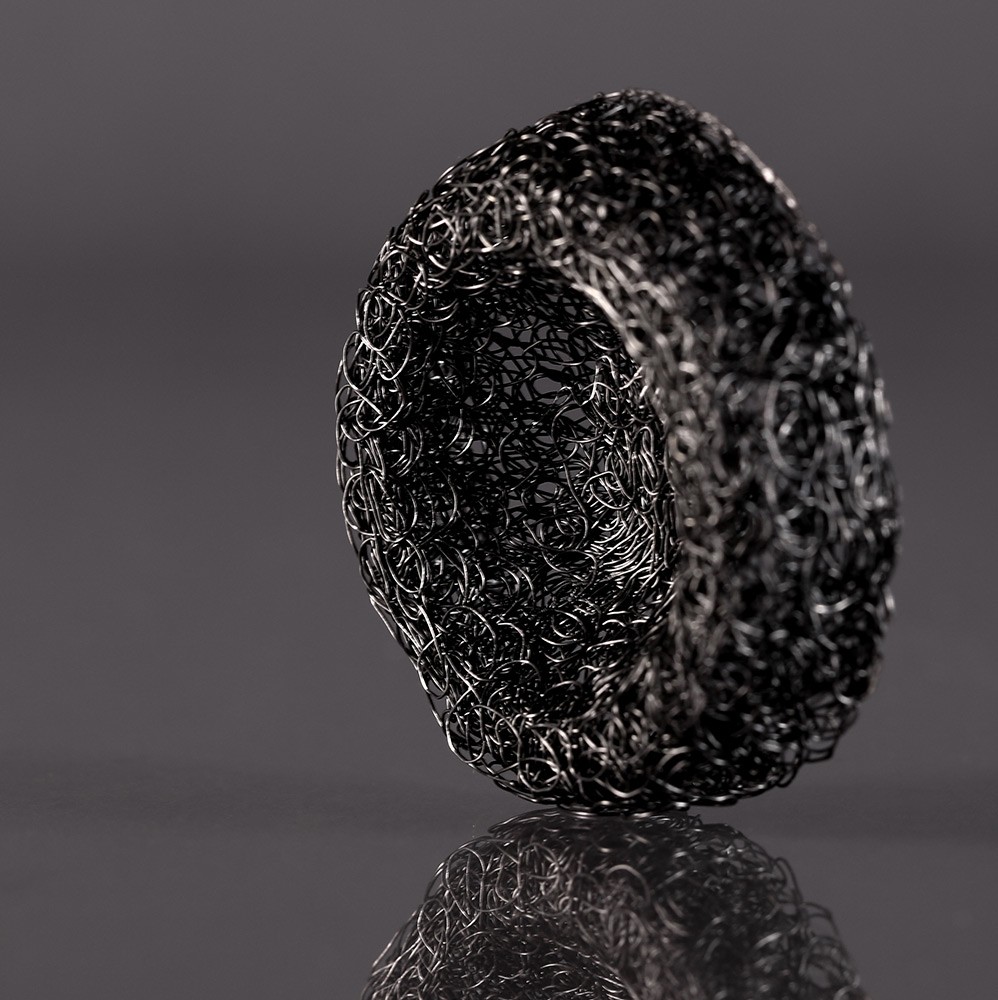

Compressing knitted wire mesh in a die creates an element that has a tortuous air path with intricate passages that also attenuate sound by absorption. This sound attenuation material is frequently used in applications where a less resilient material would fail.

The above features enable the knitted material, in a variety of forms, to reduce vibration, attenuate sound or dissipate heat. In some cases, all of these functions can be achieved in the same application. Commonly, these components have applications in automotive exhaust components, aerospace, marine and air tool industries, where thermal, vibration and sound attenuation insulation needs to be light weight, efficient and compact.