Mist Eliminators, also known as Demisters or Entrainment Separators, are efficient devices made of knitted wire mesh for liquid-gas separation.

Scroll Down

Mist Eliminators offer a cost-effective, versatile, and efficient solution for removing liquid droplets from gas streams in various industrial applications. The Mist Eliminators are designed using a bed of knitted wire mesh, creating a twisted path and a large surface area that effectively captures and separates droplets in a gas stream, promoting efficient gas purification.

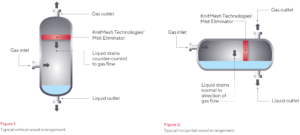

The Mist Eliminators are available in various installation options, with standard designs offering excellent separation efficiency, capable of effectively capturing droplets as small as 2 microns. Additionally, the pressure drop is typically less than 25mbar, demonstrating their effectiveness.

These Mist Eliminators are customised to fit the dimensions of the vessel or housing in which they will be installed, and with their rigid support grids, they allow for direct installation on supports like beams and rings within the vessel. Their sectional installation makes handling and access through vessel manways more convenient, and accessories such as tie wire bolting clamps and support beams are available if needed.

Mist, also known as liquid droplets, can be a by-product of various industrial processes such as chemical reactions, cooling towers, and petrochemical refining. These tiny liquid droplets suspended in process gases can hinder productivity, contaminate equipment, and lead to environmental concerns if not properly managed.

Mist Eliminators, also known as Demisters or Entrainment Separators, are devices designed to capture and remove these unwanted liquid droplets from gases, allowing for cleaner and safer operations. They function by employing specialised materials and innovative designs to efficiently separate the mist from the gas stream, preventing it from escaping into the atmosphere or causing damage to downstream equipment.