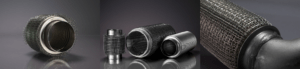

KnitMesh Technologies’ Decoupling Rings are designed for use in exhaust systems. Constructed with high-quality knitted wire mesh, typically stainless steel, they offer exceptional noise reduction and vibration control capabilities.

Download DatasheetScroll Down

KnitMesh Technologies’ Decoupling Rings are a vital component designed to withstand the harsh environments encountered in transverse mounted engines. These innovative rings provide exhaust manufacturers with an ideal solution to the significant vibration problem often associated with engine systems.

Crafted using knitted wire mesh, typically in stainless steel, these Decoupling Rings offer robustness and durability, essential in withstanding the stresses of engine operation. Their construction ensures reliable performance, even in the most demanding conditions.

One of the standout features of KnitMesh Technologies’ Decoupling Rings is the flexibility in design. They can be configured in cylinder form or tailor-made to suit specific housings, allowing for a customised solution that meets the unique requirements of individual customers. This versatility sets them apart, offering a practical and adaptable solution for a wide range of engine setups.

Knitted wire mesh is a highly versatile material used in a variety of industries because of its ability to absorb energy. The unique nature of the material allows it to absorb energy in the form of heat, vibration, and sound, making it a popular choice for many different applications.

One way that knitted wire mesh absorbs energy is through heat transfer. Because the material is made up of interlocking loops of wire, it has a large surface area that can absorb heat from its surroundings. This makes it an ideal material for use in applications that generate a lot of heat, such as high-performance engines or electronic devices. By absorbing excess heat, knitted wire mesh helps to protect these components and prevent damage.

Another way that knitted wire mesh absorbs energy is through vibration. When an object vibrates, it gives off energy in the form of sound waves. Knitted wire mesh is a highly effective material for absorbing these sound waves, as the loops of wire help to dissipate the energy and reduce the amplitude of the vibrations. This makes it an ideal material for use in applications that require noise reduction, such as in automotive exhaust systems or industrial machinery.

Lastly, knitted wire mesh can also absorb energy in the form of sound waves themselves. When sound waves pass through the material, they encounter resistance from the interlocking loops of wire, which helps to dissipate the energy and reduce the volume of the sound. This makes knitted wire mesh a popular material for use in acoustic panels and other sound insulation applications.