Knitted wire mesh is a versatile material known for its durability and unique structure. It is widely used in various industries such as automotive, aerospace, and filtration due to its excellent mechanical properties and high-performance capabilities.

Scroll Down

KnitMesh Technologies is the leading provider of premium knitted wire mesh solutions for a diverse range of industries. With a dedicated focus on innovation and expert craftsmanship, they offer superior wire mesh products designed to elevate performance and durability.

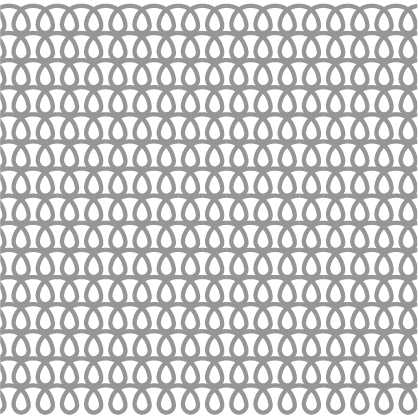

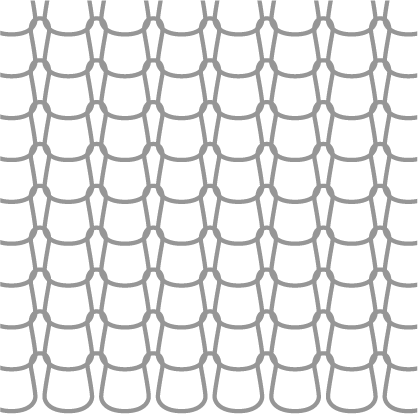

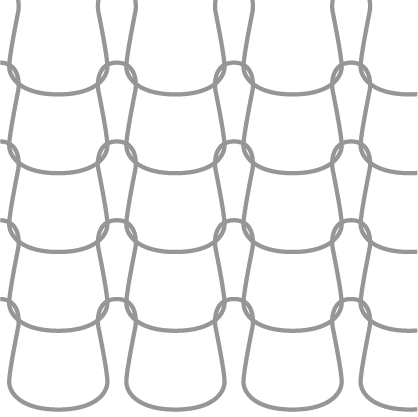

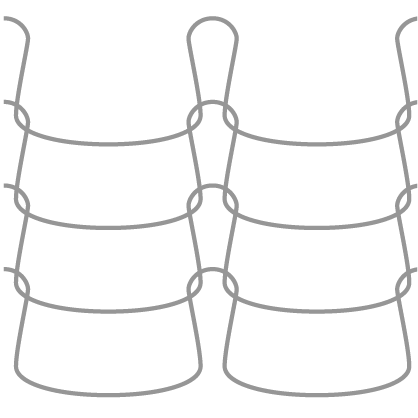

KnitMesh Technologies offers a considerable range of knitted wire mesh, specified by the number of stitches per cm. The mesh options range from 0.5 stitches per cm to 6 stitches per cm, providing versatility for practical applications.

Their meshes are categorised as fine, medium-fine, standard, coarse, and super-coarse, covering a wide range of products within these classifications.

By utilising various filament diameters, mesh sizes, and employing different crimping, calendaring, folding, layering, and rolling processes, KnitMesh Technologies offers an almost limitless product scope in the knitted wire mesh industry.

KnitMesh Technologies produces knitted wire mesh that can also be manufactured in plastic and other fibres, with the most frequently used materials including polypropylene, Hostaflon, Teflon, glass wool, and silica yarn. The figures provided for the number of stitches per cm are approximate, given the significant impact of various variables on the stitch size.

For fine meshes, the filaments are circular in section, whereas for standard, coarse, and extra coarse meshes, KnitMesh Technologies can use either circular section or flattened section filaments to increase the surface area.

This versatile type of mesh involves knitting multiple filaments of the same material or combining different materials (ie stainless steel and polypropylene)

Any material that can be drawn or spun into filament form can be used to produce a knitted mesh structure for use in the manufacture of our products including:

| Typical wire diameter (mm) | Range of natural width (mm) | Typical number of stitches per cm on length | Typical number of stitches per cm across lay flat |

|---|---|---|---|

| 0.05 - 0.15 | 6 - 165 | 3.5 | 4.4 |

| Typical wire diameter (mm) | Range of natural width (mm) | Typical number of stitches per cm on length | Typical number of stitches per cm across lay flat |

|---|---|---|---|

| 0.15 | 40 - 635 | 2.4 | 3.5 |

| Typical wire diameter (mm) | Range of natural width (mm) | Typical number of stitches per cm on length | Typical number of stitches per cm across lay flat |

|---|---|---|---|

| 0.2 - 0.35 | 30 - 1000 | 1.6 | 1.9 |

| Typical wire diameter (mm) | Range of natural width (mm) | Typical number of stitches per cm on length | Typical number of stitches per cm across lay flat |

|---|---|---|---|

| 0.2 - 0.35 | 30 - 550 | 1.6 | 0.74 |

| Typical wire diameter (mm) | Range of natural width (mm) | Typical number of stitches per cm on length | Typical number of stitches per cm across lay flat |

|---|---|---|---|

| 0.4 - 0.6 | 330 - 350 | 0.5 | 0.5 |