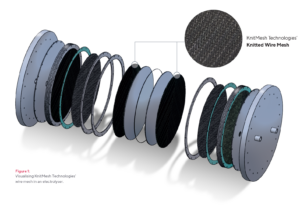

KnitMesh Technologies‘ Knitted Elastic Elements are innovative components used in electrolysers. These elements are created using high-quality knitted wire mesh, providing them with durability and flexibility.

Download BrochureRunterscrollen

KnitMesh Technologies‘ Knitted Elastic Elements, made of high-quality knitted wire mesh, are a vital component in the efficient operation of electrolysers. These elements play a crucial role in various applications within the electrolysis process, ensuring optimal performance and durability.

One of the standout features of KnitMesh Technologies‘ Knitted Elastic Elements is their high elastic range of compression, typically reaching 30%. This elasticity allows them to effectively absorb vibrations and movements during operation, contributing to the stability and reliability of the electrolyser system.

Moreover, these knitted wire mesh elements exhibit high electrical conductivity, which is essential for maintaining consistent and efficient current flow within the electrolyser. They are designed to compensate for thermal expansion, ensuring that the electrolyser can operate at different temperature conditions with minimal impact on performance.

KnitMesh Technologies‘ Knitted Elastic Elements can be custom-produced to any initial height required, offering flexibility and adaptability to meet specific application needs. Additionally, these elements are available in sizes up to 2 metres in diameter as a single piece, making them suitable for a wide range of electrolyser configurations and requirements.

In 2025, KnitMesh Technologies partnered with a leading manufacturer of woven wire mesh, giving you access to an even broader range of solutions. You can now source both knitted wire mesh and woven wire mesh directly from a single, trusted supplier. These materials can be combined, including welded together, to create a complete and fully integrated solution tailored to your needs. In addition, KnitMesh Technologies can now also supply full electrolyser cell assemblies, helping you streamline your supply chain and simplify your hydrogen projects.

Electrolysis is the process of breaking down a substance into its individual components using an electric current. This process is widely used in industry as well as in scientific research. In simple terms, electrolysis involves the use of an electrolytic cell that consists of two electrodes, an anode and a cathode, and an electrolyte solution that conducts electricity.

When an electric potential is applied across the anode and cathode, the ions in the electrolyte solution move towards their respective electrodes due to the attraction of opposite charges. At the anode, positive ions lose their electrons and become oxidised, while at the cathode, negative ions gain electrons and become reduced. This results in the formation of new substances, which can be isolated through various processes.

One important application of electrolysis is in the production of hydrogen gas, which is used in various industries as well as for energy production. In this process, water is used as the electrolyte solution, and the electric current is used to split the water molecule into its constituent hydrogen and oxygen atoms.

Knitted Elastic Elements are used in electrolysers to provide mechanical support and structure to the electrodes and other components of the electrolysis cell. These elements can help maintain the proper spacing between electrodes, prevent them from shifting or moving during operation, and ensure uniform distribution of the electrolyte.