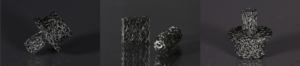

KnitMesh Technologies‘ Actuator Filters are meticulously crafted using knitted wire mesh, ensuring exceptional quality and reliability for filtering applications.

Runterscrollen

KnitMesh Technologies‘ Actuator Filters play a crucial role in maximising the entrapment of particulates from propellants and enhancing the cooling of expanding gas after activation. These filters are specially designed to cater to the demanding requirements of various industries where precision and reliability are paramount.

Crafted from high-quality knitted wire mesh, KnitMesh Technologies‘ Actuator Filters boast a unique construction that ensures uniform compression throughout the filter. This characteristic not only enhances the filtering capabilities of the mesh but also contributes to its durability and longevity in challenging environments.

One of the standout features of KnitMesh Technologies‘ Actuator Filters is their excellent flow properties combined with a large surface area. This design aspect allows for efficient filtration while maintaining optimal airflow. The filters are engineered to withstand high shock loadings, making them suitable for applications that experience sudden changes in pressure or force.

Moreover, KnitMesh Technologies‘ Actuator Filters are built to operate effectively in high-temperature, corrosive, and hostile environments. This versatility makes them a preferred choice for critical applications where standard filters may not suffice.

In industrial processes where the filtration of liquids and gases is crucial, having the right materials can significantly impact efficiency and overall quality. One material that has proven to be highly effective in boosting filtration efficiency is knitted wire mesh.

Knitted wire mesh is specifically designed to provide superior filtration capabilities. Its unique structure, created by interlocking wire in a precise pattern, results in a high surface area with tiny spaces or pores. These characteristics make knitted wire mesh ideal for capturing impurities and contaminants during the filtration process.

The key to its efficiency lies in the precise control of pore size and density. This ensures that particles of various sizes are effectively captured, making it a reliable solution for microfiltration needs. This ability to capture contaminants with a high capture rate makes knitted wire mesh an efficient choice for a wide range of industrial filtration applications.

Furthermore, knitted wire mesh is highly customisable, allowing for tailored solutions to meet specific filtration requirements. It can be manufactured using different metals such as stainless steel, copper, and aluminium, making it suitable for diverse industrial needs.