When it comes to knitted wire mesh and porous media, KnitMesh Technologies is unrivalled.

This fact is especially true in the fields of hydrogen production, electrolysis, fuel cells, and power-to-gas conversion.

Download BrochureRunterscrollen

Hydrogen producers from all over the world work with KnitMesh Technologies to develop and produce unique knitted wire mesh and porous media. Electrolysis, fuel cells, and power-to-gas conversion are just a few of the growing fields that rely on these product lines.

Knitted wire mesh is now widely used in various membrane technologies, including Polymer Electrolyte Membranes, Proton Exchange Membranes, and Ion Exchange Membranes.

This specialised material improves electrical and pressure contact in cell stacks and modular cell cartridges by connecting cells, divider stacker plates, membranes, and diaphragms.

Electrolysers frequently experience issues with electrical contact resistance (ECR), which reduces efficiency and increases operating costs.

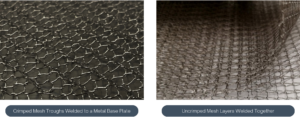

Mesh-Jointing is a unique welding process offered by KnitMesh Technologies that completely eliminates electrical contact resistance. The process is optional and involves creating a single, bonded structure between knitted wire mesh, metal plates and other components, such as bipolar plates, porous structures, metallic felt, and expanded metal.

Knitted wire mesh is available in any apparent width and manufactured from only the finest metal wire, including nickel, titanium, and stainless steel grade 316. KnitMesh Technologies can also process additional materials, such as platinum, gold, carbon fibre, glass wool, and coated or plated metals.

This cutting-edge material is formed from a network of interlocking loops (typically using 0.05mm to 0.35mm diameter wire) and finds widespread use in the hydrogen production industry.