KnitMesh Technologies is the leading manufacturer of high-quality knitted wire mesh products, including Mist Eliminators. If you are looking for more information about Mist Eliminators and how they can benefit your processes, this blog post will answer some frequently asked questions.

FAQs About Mist Eliminators

Q: What is a Mist Eliminator?

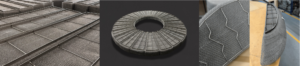

A Mist Eliminator, also known as a Demister or Entrainment Separator, is a device designed to remove liquid droplets or mist from a gas stream. It ensures that the gas leaving a process is free from contaminants, providing a cleaner and safer environment.

Q: How does a Mist Eliminator work?

A Mist Eliminator typically consists of knitted wire mesh, which is designed to capture and coalesce the mist droplets present in the gas stream. As the gas passes through the mesh, the liquid droplets adhere to the wires and coalesce into larger droplets, which eventually fall back into the process stream.

Q: What are the advantages of using knitted wire mesh for mist elimination?

Knitted wire mesh offers several advantages for mist elimination, including high efficiency in capturing mist droplets, low pressure drop, corrosion resistance, and durability. Additionally, knitted wire mesh Mist Eliminators are easy to clean and maintain, providing long-term cost savings.

Q: Where are Mist Eliminators used?

Mist Eliminators are used in a wide range of industries, including petrochemical, chemical processing, pharmaceutical, and power generation. They are commonly found in scrubbers, evaporators, distillation columns, and other equipment where gas-liquid separation is required.

Q: Can Mist Eliminators handle high-temperature applications?

Yes, Mist Eliminators are designed to withstand high temperatures and can be constructed using materials such as stainless steel or other heat-resistant alloys. This makes them suitable for applications where the gas stream may have elevated temperatures.

Q: Are Mist Eliminators resistant to corrosion and chemical exposure?

Mist Eliminators are highly resistant to corrosion and are capable of withstanding exposure to a wide range of chemical environments. This makes them suitable for use in corrosive gas streams found in industries such as chemical processing and oil refining.

Q: Can Mist Eliminators be retrofitted into existing equipment?

Yes, Mist Eliminators can be engineered to fit into existing equipment and retrofit applications. Their customisable design and flexibility make them suitable for integration into various industrial processes without the need for extensive modifications to existing infrastructure.

Q: How often should Mist Eliminators be replaced?

The lifespan of Mist Eliminators depends on various factors, such as the operating conditions and the nature of the process. Regular inspections and maintenance can help both extend life expectancy and determine when replacement is necessary.

Q: How do I select the right Mist Eliminator for my application?

When selecting a Mist Eliminator, it is important to consider factors such as gas flow rate, operating temperature, pressure drop limitations, and the type of contaminants present in the gas stream. KnitMesh Technologies offers a range of customisable Mist Eliminators to meet specific application requirements.

Mist Eliminators from KnitMesh Technologies

KnitMesh Technologies is the leading manufacturer of Mist Eliminators made from high-quality knitted wire mesh. Knitted wire mesh Mist Eliminators offer excellent mist removal efficiency, low pressure drop, and high mechanical strength, making them ideal for demanding industrial applications.

With a wide range of materials, sizes, and configurations available, KnitMesh Technologies‘ Mist Eliminators can be customised to meet the unique requirements of any application.

Contact KnitMesh Technologies

For more information about KnitMesh Technologies‘ Mist Eliminators and other knitted wire mesh products, email enquiries@knitmesh.com or call +44 (0)1352 717 640.