KnitMesh Technologies is the leading global supplier of Mist Eliminators, providing innovative solutions for a wide range of industries. In this blog post, we will delve into the basics of Mist Eliminators, explaining how they work and highlighting why they are essential in various applications.

What are Mist Eliminators?

Mist Eliminators, also known as Demisters or Entrainment Separators, are devices designed to remove liquid droplets or mist from gas streams. These mist droplets can be generated through various processes, such as evaporative cooling, condensation, or chemical reactions. Mist Eliminators are crucial in industries where the presence of mist can result in operational inefficiencies, environmental hazards, or safety risks.

How do Mist Eliminators Work?

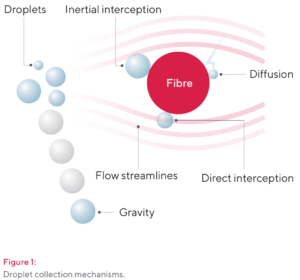

Mist Eliminators work on the principle of coalescence. They are typically constructed using a mesh pad composed of interlocking layers of knitted wire mesh. This construction provides a tortuous path for the gas stream, promoting the collision and coalescence of the mist droplets as they pass through the mesh.

The knitted wire mesh captures the fine liquid droplets, allowing them to merge and form larger droplets. The larger droplets, being heavier, then separate from the gas stream due to gravity and are collected in a drain. The cleaned gas stream can then proceed through the system without any mist contamination.

Why do You Need Mist Eliminators?

1. Efficiency and Productivity

In industrial processes, the presence of mist can negatively impact efficiency and productivity. Mist can obstruct the flow of gases, reducing the effectiveness of equipment such as compressors, heat exchangers, and absorbers. By incorporating Mist Eliminators into these systems, the operational efficiency can significantly improve, allowing for increased productivity and reduced downtime.

2. Environmental Protection

Mist Eliminators play a crucial role in protecting the environment by preventing mist emissions. Uncontrolled mist emissions can release hazardous substances into the atmosphere, posing risks to human health and the environment. The installation of Mist Eliminators ensures compliance with environmental regulations and reduces the impact of harmful emissions.

3. Equipment Protection and Maintenance

Mist Eliminators act as a safeguard for valuable equipment. Fine droplets in gas streams can result in both erosion and corrosion, leading to premature wear and tear, increased maintenance costs, and shortened equipment lifespan. Incorporating Mist Eliminators protects equipment from these damaging effects, reducing maintenance requirements and extending equipment life.

4. Safety

In certain industries, the presence of mist can pose a safety risk. In applications where mist can be flammable or explosive, it is vital to prevent the accumulation of mist in the gas stream, reducing the likelihood of accidents or fires. Mist Eliminators provide an effective mitigation measure, ensuring safe operations and protecting personnel and facilities.

Mist Eliminators From KnitMesh Technologies

KnitMesh Technologies is the leading provider of high-performance Mist Eliminators tailored to meet specific customer requirements in a wide range of industries. With decades of expertise in knitted wire mesh technology and engineering, KnitMesh Technologies offers a range of Mist Eliminators designed to deliver optimal separation efficiency and durability.

The Mist Eliminators from KnitMesh Technologies are precision-engineered using advanced materials and manufacturing processes to ensure reliable performance even in demanding environments. Whether for chemical processing, oil and gas production, or power generation, KnitMesh Technologies‘ Mist Eliminators are designed to effectively remove mist and droplets from gas streams, safeguarding equipment and improving process efficiency.

Contact KnitMesh Technologies

To learn more about KnitMesh Technologies‘ comprehensive range of Mist Eliminators and how they can benefit your operations, contact enquiries@knitmesh.com or call +44 (0)1352 717 640.